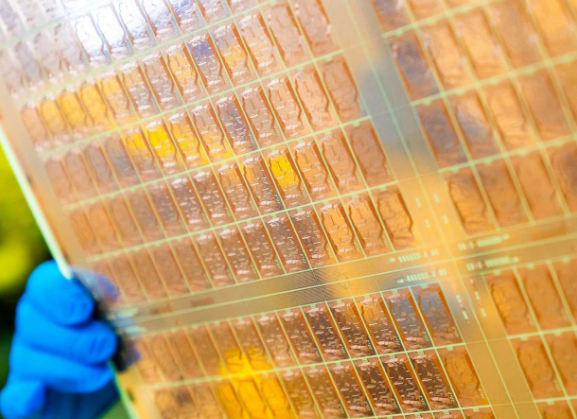

September 15, 2023 – In a groundbreaking development reported by Reuters today, Tesla has achieved a significant milestone in its automotive manufacturing technology. This advancement in their gigacasting technique promises to revolutionize the production of electric vehicles and bring Elon Musk one step closer to his goal of halving production costs.

According to insider sources, Tesla has pioneered the use of colossal hydraulic presses with clamping forces ranging from 6000 to 9000 tons. These mammoth machines are employed to forge the front and rear chassis structures of the Model Y through a process known as gigacasting, effectively reducing production expenses.

What sets this breakthrough apart is its potential to consolidate nearly 400 conventional automotive components into a single unit, almost entirely casting the intricate underbelly of electric vehicles. This innovation could establish a formidable technological moat for Tesla, insulating them from rivals in the fiercely competitive electric vehicle market.

Reports suggest that with the implementation of this gigacasting technology, Tesla could shorten the development time for new vehicles to a mere 18-24 months, a substantial improvement compared to the current industry standard of 3-4 years for new car development.